Next Gen Adhesives and Sealants Market Poised for Transformative Growth Through 2033

Next Gen Adhesives and Sealants market to hit 125.21 billion dollars by 2033 as EVs, smart construction and sustainable materials accelerate global demand.

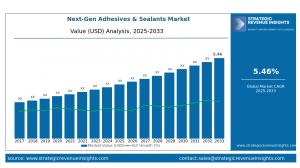

LONDON, UNITED KINGDOM, UNITED KINGDOM, November 19, 2025 /EINPresswire.com/ -- The global Next Gen Adhesives and Sealants market is entering a defining phase of innovation, sustainability driven reform, and strategic realignment across key industries. With applications expanding in automotive, construction, electronics, healthcare, and high-performance packaging, this category has become a quiet backbone of modern manufacturing and infrastructure development. As organizations shift toward lightweighting, modular engineering, and energy efficient production, advanced adhesives and sealants have moved from supporting components to essential enablers of product integrity and long-term durability. According to recent findings from Strategic Revenue Insights, the market was valued at 77.6 billion dollars in 2024 and is projected to reach 125.21 billion dollars by 2033, supported by a steady CAGR of 5.46 percent.A detailed overview is available at the Next Gen Adhesives and Sealants Market page at https://www.strategicrevenueinsights.com/industry/next-gen-adhesives-sealants-market where readers can explore the segment’s complete scope.

The role of advanced bonding materials has expanded far beyond traditional joining techniques. In an era where manufacturers seek to eliminate weight, reduce assembly complexity, and achieve higher mechanical and chemical resilience, the industry has accelerated the adoption of innovations ranging from reactive adhesives to next generation hot melt systems and biocompatible sealants. From electric vehicle battery packs to high performance building envelopes and consumer electronics, next generation bonding solutions are now embedded across global value chains and are shaping design possibilities for the next decade.

Market Trends

The current wave of change within the Next Gen Adhesives and Sealants market is driven by a convergence of sustainability expectations, rising technological sophistication, and a shift in consumer and regulatory preferences. Sustainability has become a defining trend as companies adopt greener formulations and low emission products. Manufacturers in both developing and mature markets are under increasing pressure to reduce volatile organic compound levels, phase out harmful solvents, and divert from petrochemical intensive production. Water based adhesives are gaining ground as climate strategies become procurement criteria across automotive and construction players.

At the same time, the demand for lightweight vehicles, flexible packaging, and compact electronics is reshaping end user expectations. Modern automotive design depends on bonding strategies that can withstand mechanical strain, temperature fluctuation, and electrical insulation requirements. The move toward electric vehicles has intensified the need for adhesives that resist thermal runaway and ensure strong structural performance. Meanwhile, flexible packaging continues to surge as global e commerce raises the bar for durability, tamper resistance, and long lasting shelf performance. These changes have pulled the market firmly toward multi substrate adhesives and sealants that can adapt to varied surfaces, higher thermal stress, and increasing mechanical loads.

Consumer preferences also play a significant role. The shift to minimalistic products, modern architectural surfaces, and transparent sealing solutions has created a niche for clean finish adhesives and sealants that are aesthetically invisible yet perform under considerable mechanical pressure. Industries such as electronics and medical devices demand adhesives that offer micro precision and biocompatibility. With the rise of personalized smart devices, companies are now prioritizing low cure temperatures, fast setting times, and formulations that support delicate internal structures.

Browse the associate report:

https://www.strategicrevenueinsights.com/ja/industry/next-gen-adhesives-sealants-market

https://www.strategicrevenueinsights.com/kr/industry/next-gen-adhesives-sealants-market

https://www.strategicrevenueinsights.com/de/industry/next-gen-adhesives-sealants-market

https://www.strategicrevenueinsights.com/da/industry/next-gen-adhesives-sealants-market

https://www.strategicrevenueinsights.com/es/industry/next-gen-adhesives-sealants-market

https://www.strategicrevenueinsights.com/pt/industry/next-gen-adhesives-sealants-market

https://www.strategicrevenueinsights.com/it/industry/next-gen-adhesives-sealants-market

https://www.strategicrevenueinsights.com/fr/industry/next-gen-adhesives-sealants-market

Technological Advancements

Technology has always played a defining role in the adhesives and sealants market, but the current phase of innovation represents a leap in sophistication. Automation, digital manufacturing, and material science breakthroughs are rewriting the industry’s capabilities. One of the most notable shifts is the integration of adhesives with automated assembly lines, where robotic dispensing systems ensure precision mixing, controlled application, and reduced waste. This is particularly relevant for automotive and electronics manufacturers who require consistent bond strength and quality across thousands of units per day.

Emerging material technologies are driving equally important changes. Bio based adhesives derived from plant sources are becoming increasingly relevant as companies step away from petrochemical dependency. These products offer improved biodegradability and align with sustainability commitments without compromising mechanical performance. Smart adhesives also represent a growing category. These materials change color based on bond strength, indicate curing progress, or enhance thermal conductivity for electronics. They are particularly useful in battery manufacturing where heat dissipation, vibration resistance, and structural stability must coexist.

Advancements in hot melt systems, water based dispersions, and UV curable adhesives are redefining productivity metrics. Hot melt adhesives now provide stronger holding capacity, faster setting, and improved compatibility with automated systems. UV curable adhesives have found widespread adoption in electronics and medical devices due to their rapid curing under ultraviolet light and their ability to deliver precise bonding with minimal heat exposure. Meanwhile, developments in hybrid polymer sealants that combine the best characteristics of silicone and polyurethane have introduced new performance thresholds for construction and industrial applications.

Smart packaging is another major technological shift. As brands move toward tamper evident, freshness preserving, and sustainability aligned packaging solutions, adhesives have become crucial to new label technologies, carton sealing techniques, and barrier preserving structures. Digital printing, RFID integration, and micro perforation technologies all require adhesives capable of maintaining integrity without reacting to inks, coatings, or embedded sensors.

Sustainability Challenges

Even with sweeping innovation, the Next Gen Adhesives and Sealants industry faces pressing environmental challenges that demand urgent and coordinated responses. The reliance on petrochemical feedstocks remains a persistent issue, particularly in solvent based adhesives that release volatile organic compounds during production or application. Regulatory agencies in North America, Europe, and parts of Asia have intensified oversight, setting stricter limits on emission levels and chemical exposure thresholds. For instance, the European Union has tightened both REACH and Construction Products Regulation compliance, pushing manufacturers to reengineer their product portfolios.

Raw material volatility complicates the sustainability landscape further. Fluctuations in crude oil prices influence resin availability, rising demand for bio based content, and cost pressures across the supply chain. These pressures often slow the transition to greener alternatives, especially for small and mid sized manufacturers. Moreover, recycling challenges associated with bonded materials complicate circular economy strategies. Adhesives used in multilayer packaging, automotive components, and composite structures often hinder material separation, reducing recycling yields.

In response, the industry is accelerating efforts to develop low VOC adhesives, solvent free technologies, and water based dispersions. According to recent market data, the adoption of water based adhesives has risen faster than any other category, supported by a compound annual growth rate exceeding seven percent in certain segments. Research groups are also experimenting with biodegradable adhesives that can be dissolved or separated during recycling. Supply chain traceability and carbon accounting have also become priorities as multinational companies seek to quantify their carbon footprints and report on sustainability metrics.

Despite the challenges, the commitment toward environmental responsibility remains strong. Investments in green chemistry, plant based polymers, and hybrid formulations have increased across major manufacturers. These initiatives serve both regulatory compliance and rising consumer expectations in a market that increasingly demands transparency and environmental stewardship.

Market Analysis

The Next Gen Adhesives and Sealants market presents a dynamic and competitive landscape shaped by global demand, technological evolution, and shifting regulatory patterns. With a valuation of 77.6 billion dollars in 2024 and a projected climb to 125.21 billion dollars by 2033, the market remains on a sustained upward trajectory. The five point four six percent CAGR indicates both stability and resilience despite broader macroeconomic pressures such as raw material inflation and energy cost fluctuations.

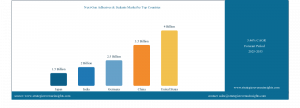

Asia Pacific holds the largest regional share, driven by rapid industrialization, construction booms, and the expansion of automotive and electronics manufacturing hubs. China and India continue to lead demand for both industrial and infrastructure applications. North America and Europe remain strong markets with high adoption of advanced adhesives, particularly in EVs, aerospace, healthcare devices, and high end construction.

The competitive landscape includes established players such as Henkel AG, 3M Company, Sika AG, H B Fuller, Arkema Group, Dow, and BASF SE. These companies continue to invest in research, regional expansion, and partnerships to broaden their product portfolios. Mergers and acquisitions have increased across the sector as manufacturers seek to integrate complementary technologies, enter new end user markets, and streamline production footprints.

Demand patterns also vary significantly by application. Automotive remains the largest single sector, with increasing focus on structural adhesives, battery bonding, and vibration resistant solutions. Construction is experiencing strong demand for high elasticity sealants, weather resistant adhesives, and advanced flooring solutions. Electronics continues to grow steadily, driven by printed circuit board bonding, miniaturization, and thermal management adhesives. Healthcare, while smaller in scale, is rising due to biocompatible adhesives for medical devices, wound care, and diagnostic equipment.

Future Outlook

The future of the Next Gen Adhesives and Sealants market is defined by regulatory shifts, electrification trends, smart infrastructure investments, and the broader push toward sustainable materials. Regulatory bodies are expected to impose tighter emissions standards, compelling manufacturers to scale up production of low VOC and solvent free adhesives. This trend will likely reshape formulation strategies, supply chain dependencies, and pricing structures.

The automotive industry will continue to play a pivotal role. As global EV adoption accelerates, manufacturers will require adhesives that can tolerate high thermal loads, support battery cell assembly, and offer structural reinforcement for lightweight body materials. Companies may see increased demand for thermal interface adhesives, fire resistant sealants, and next generation under hood bonding solutions.

Construction will remain another critical growth engine. As cities adopt climate resilient and energy efficient building practices, the need for advanced sealing technologies, structural bonding systems, and hybrid polymer sealants will intensify. Smart building technologies may further increase demand for adhesives used in sensors, insulation systems, and modular construction components.

Packaging will continue its transformation as sustainability expectations rise. Future adhesives will likely incorporate compostable characteristics, improved barrier performance, and compatibility with recycling streams. Meanwhile, electronics and medical devices will increasingly demand micro precision adhesives, improved thermal management materials, and higher durability under miniaturized conditions.

Beyond these trends, artificial intelligence and automation are expected to redefine adhesive dispensing, quality assurance, and supply chain planning. Predictive analytics may become central to inventory management, resin formulation, and process optimization. Companies that harness data driven manufacturing will maintain a decisive competitive advantage.

The Next Gen Adhesives and Sealants industry sits at the intersection of material science innovation, sustainability transformation, and global manufacturing evolution. Its influence extends across automotive, construction, electronics, healthcare, and packaging, making it a vital component of modern industrial ecosystems. As the world advances toward electrification, smart infrastructure, and circular economy models, adhesives and sealants will continue to shape the physical products and structures that define global progress. Readers seeking deeper insights, detailed segmentation analysis, and strategic forecasts can explore more at Strategic Revenue Insights at https://www.strategicrevenueinsights.com for comprehensive research and expert guidance.

Related Reports:

https://www.strategicrevenueinsights.com/industry/materials-for-next-generation-lithography-market

https://www.strategicrevenueinsights.com/industry/next-gen-adhesives-sealants-market

https://www.strategicrevenueinsights.com/industry/next-gen-composites-for-industrial-applications-market

https://www.strategicrevenueinsights.com/industry/next-gen-adhesives-sealants-market

https://www.strategicrevenueinsights.com/industry/next-gen-patient-empowerment-platforms-market

https://www.strategicrevenueinsights.com/industry/next-gen-supply-chain-market

https://www.strategicrevenueinsights.com/industry/next-generation-antibody-drug-market

https://www.strategicrevenueinsights.com/industry/next-generation-battery-market

https://www.strategicrevenueinsights.com/industry/next-generation-biologics-biosimilars-market

https://www.strategicrevenueinsights.com/industry/next-generation-cloud-streaming-messaging-platform-market

About Us:

Strategic Revenue Insights Inc., a subsidiary of SRI Consulting Group Ltd, empowers organizations worldwide with data-driven market intelligence. Headquartered in London, United Kingdom, we deliver syndicated research reports, tailored consulting solutions, and actionable insights that equip clients to make confident, future-focused strategic decisions.

Our team of seasoned analysts-based in London and connected globally-continuously tracks markets, identifies emerging trends, and uncovers growth opportunities to support long-term client success. As part of SRI Consulting Group Ltd, we are committed to accuracy, clarity, and practical relevance, helping businesses navigate competitive landscapes, optimize strategies, and accelerate revenue growth.

By combining rigorous research methodologies with deep industry expertise, Strategic Revenue Insights Inc. provides organizations with a comprehensive market perspective that drives measurable results and sustained competitive advantage.

Media Contact:

Company Name: Strategic Revenue Insights Inc.

Contact Person: Ashwani

Email: sales@strategicrevenueinsights.com

Phone: +44 7877403352

Address: Suite10 Capital House 61 Amhurst Road, E8 1LL

City: London

State: London

Country: United Kingdom

Website: www.strategicrevenueinsights.com

Rohit Bhisey

Strategic Revenue Insights Inc.

+44 7877 403352

sales@strategicrevenueinsights.com

Visit us on social media:

LinkedIn

Facebook

YouTube

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.